Technical Topics

What are the main considerations for the selection of industrial and commercial photovoltaic inverters?

Before the design of photovoltaic power plant systems (especially large-scale industrial and commercial photovoltaic power plants and ground-based power plants), a clear understanding of the functions of the nuclear "core" inverters of photovoltaic power plants and flexible application will reduce system investment and operation and maintenance costs. Improve investment income. This article will specifically introduce the inverter functions that need to be considered in industrial and commercial photovoltaic projects.

1. Flexible use of super configuration

Due to factors such as component attenuation, line loss, system loss, insufficient illumination, etc., proper over-distribution can effectively improve the overall revenue of the power station system and has been widely used. The overmatching capability of the inverter has become an important reference index for inverter selection.

In the photovoltaic system, the design engineer matches the total capacity of the photovoltaic modules to be larger than the capacity of the inverter. This situation is called over-distribution. The reason is that photovoltaic systems often have problems such as component power attenuation, dust shielding, and line loss. In addition, the difference in lighting conditions in different regions will affect the revenue of the photovoltaic system.

Due to factors such as component attenuation, line loss, system loss, insufficient illumination, etc., proper over-distribution can effectively improve the overall revenue of the power station system and has been widely used. The overmatching capability of the inverter has become an important reference index for inverter selection.

In the photovoltaic system, the design engineer matches the total capacity of the photovoltaic modules to be larger than the capacity of the inverter. This situation is called over-distribution. The reason is that photovoltaic systems often have problems such as component power attenuation, dust shielding, and line loss. In addition, the difference in lighting conditions in different regions will affect the revenue of the photovoltaic system.

Appropriate over-distribution can increase the overall revenue of the power station system, and it has been accepted and widely used by power station owners.

It is worth noting that it is not enough to pay attention to the over-distribution capacity (over-distribution ratio) of the DC side of the inverter, and the AC overload capacity of the inverter (the output capacity of the AC side) is also important. The overload capacity of the inverter can effectively reduce the abandonment rate and the machine's overload working time, and expand the proportion of over-provisioning components.

2. Adapt to high-efficiency components

With the large-scale application of high-efficiency components, the DC input current of the inverter has been increasing.

3. Compatible with copper and aluminum cables

3. Compatible with copper and aluminum cables

Compared with the cost of copper cables, aluminum cables are lower in cost, easier to install, and lighter in weight. Reasonable cables and their laying methods can not only reduce the construction cost of the photovoltaic system, but also improve the operational efficiency and stability of the photovoltaic system. Aluminum wire is gradually becoming a popular solution. However, under the same overcurrent capacity, the wire diameter of the aluminum wire is larger than that of the copper wire, which requires the inverter to support a larger AC connector.

4. Remember that the grid is friendly

4. Remember that the grid is friendly

The main factors that affect the friendliness of the grid are power factor, current harmonics, and DC components. Power limitation and anti-backflow scenarios that widely exist in industrial and commercial projects.

The inverter detects the status of selling electricity to the grid through an external CT or Meter. When the load cannot absorb the electricity generated by the photovoltaic, the CT or meter detects the status of selling electricity and will send an instruction to the inverter to enable The output power of the inverter is matched with the load, so as to achieve the state of not selling electricity to the grid.

The inverter detects the status of selling electricity to the grid through an external CT or Meter. When the load cannot absorb the electricity generated by the photovoltaic, the CT or meter detects the status of selling electricity and will send an instruction to the inverter to enable The output power of the inverter is matched with the load, so as to achieve the state of not selling electricity to the grid.

PREV:Understand the working principle of photovoltaic inverters in one article

NEXT:How to Control Leakage Current in Solar Inverter

Share

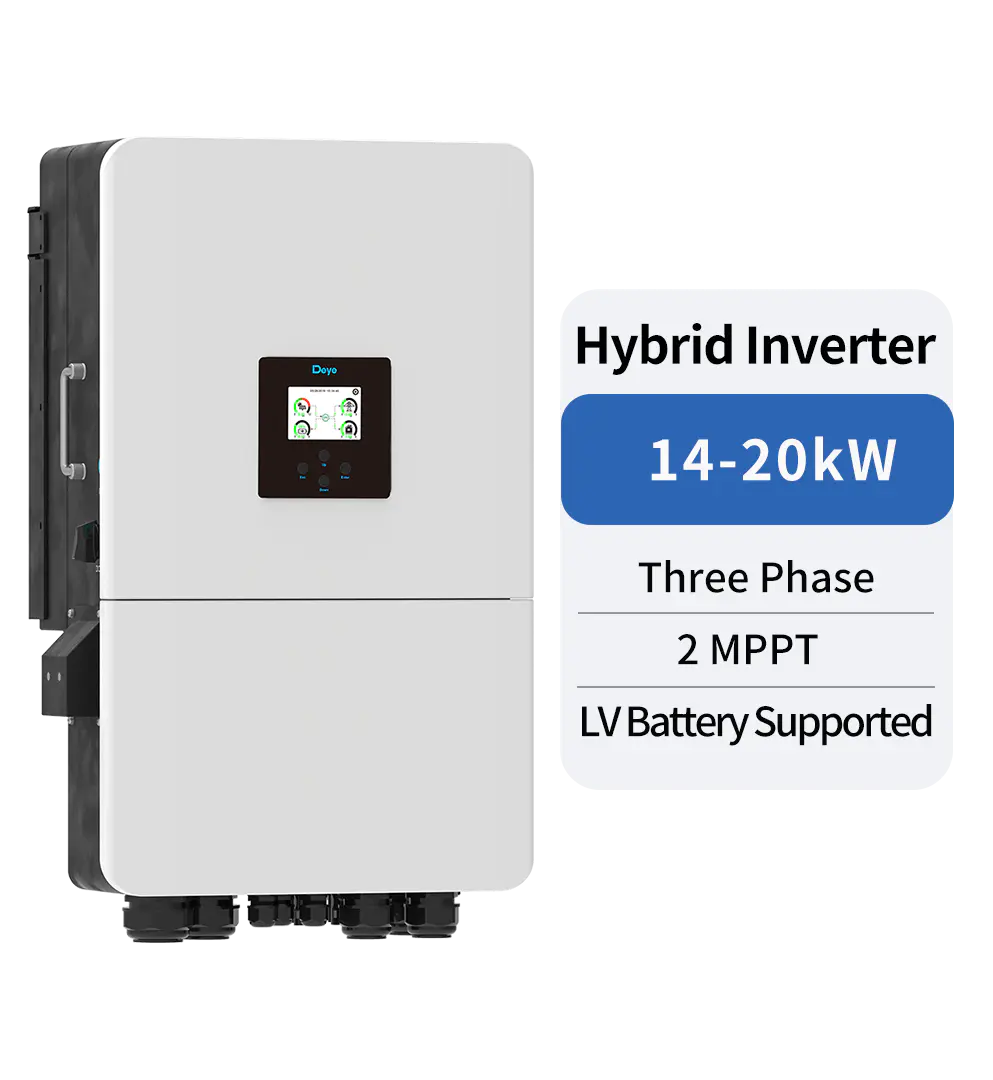

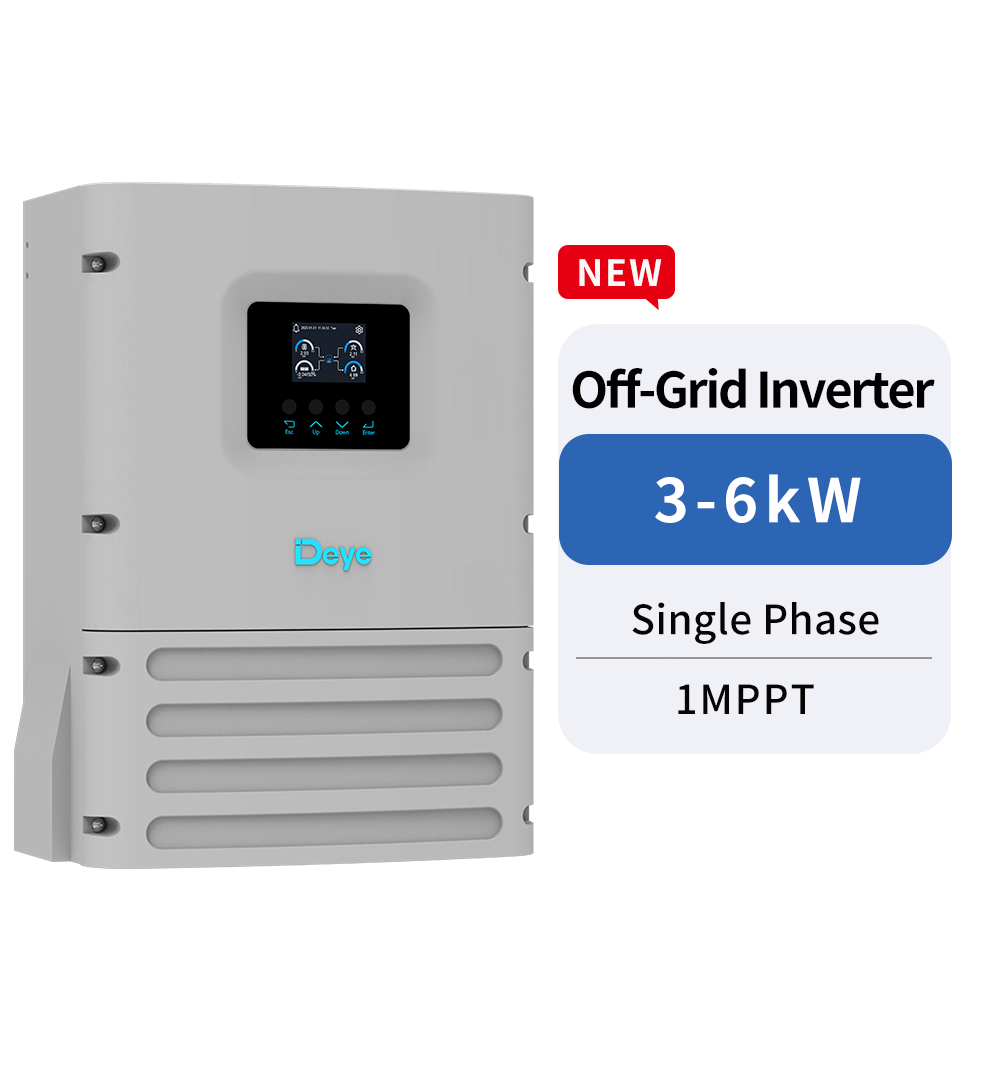

Product recommendations

news recommendations

-

-

Green Industry, Bright Future: Deye Distributor Summit – Dubai 2025 Concludes Successfully

Green Industry, Bright Future: Deye Distributor Summit – Dubai 2025 Concludes SuccessfullyIn November 2025, Deye Group successfully hosted the “Green Industry, Bright Future—Deye 2025 Dubai ...

-

Deye’s Malaysia Johor Manufacturing Base Officially Breaks Ground — A Key Step Forward in Its Globalization Strategy

Deye’s Malaysia Johor Manufacturing Base Officially Breaks Ground — A Key Step Forward in Its Globalization StrategyOn October 2, 2024, Deye Group (hereinafter referred to as “the Company”) held a groundbreaking cer...

China - 简体中文

China - 简体中文 Global - English

Global - English Brazil - Português

Brazil - Português Netherlands - Dutch

Netherlands - Dutch Italy - Italiano

Italy - Italiano Germany - Deutsch

Germany - Deutsch Spain - Español

Spain - Español France - Français

France - Français Vietnam - Tiếng Việt

Vietnam - Tiếng Việt Poland - Polski

Poland - Polski Australia - English

Australia - English Japan - 日本語

Japan - 日本語